PMSM three phase DC motor

The development of science and technology advances by leaps and bounds,in a variety of intelligent products,the motor plays avital role. This text will briefly introduce a PMSM three-phase DC motor, hereinafter referred to as PMSM motor. Compared with the

regular brush motor, the PMSM motor eliminates the carbon brush

device, instead of the method of current change, which makes the motor structure more streamlined, and the durability has been

greatly improved. PMSM motor has a relatively wide range of torque and speed adjustable, and the control method is quite flexible. It can not only be controlled by the six-step square wave method like BLDC motor, but also achieve more accurate control through the

sin ine wave method combining FOC and SVPWM. PMSM motor application is flexible, according to the use of the environment, can customize the size size, protection level, voltage, current limit, speed,

torque and other parameters.

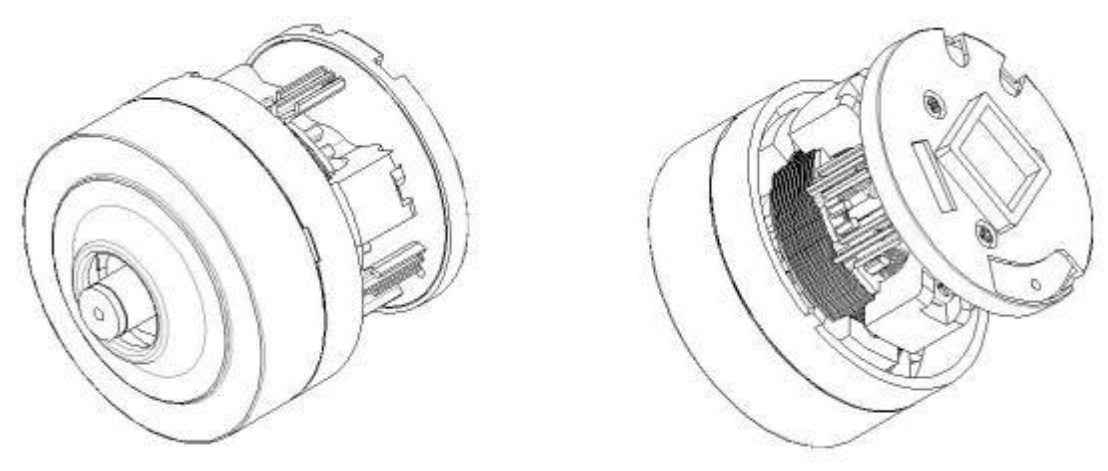

As shown in the figure below (1), a PMSM motor used for a vacuum cleaner is displayed. The motor maximum outer diameter of φ 65mm, total length of 80mm, DC 24V power supply, 17A, speed can reach

more than 60000 RPM, is a real high speed quality motor.

Figure (I)

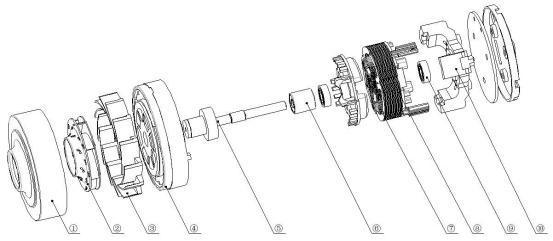

Next, let's take this BLDC motor apart, and make a brief introduction to some of the important parts.

Figure (II)

See Figure Figure (II):

① Cover shell, using high temperature hot riveting process molding, surface fingerprint galvanizing treatment,

effectively protect the cavity at the same time, taking into account the beauty.

② Inner impeller assembly, made of more than ten manganese steel stamping parts riveted, precise structure, stable and reliable.

③ The outer impeller, using high-performance PEEK material, not afraid of high temperature, not easy to deformation,

durable.

④ carrier, high standard nylon composite, hot flow injection molding, details in place, green environmental protection.